|

What is UV energy?

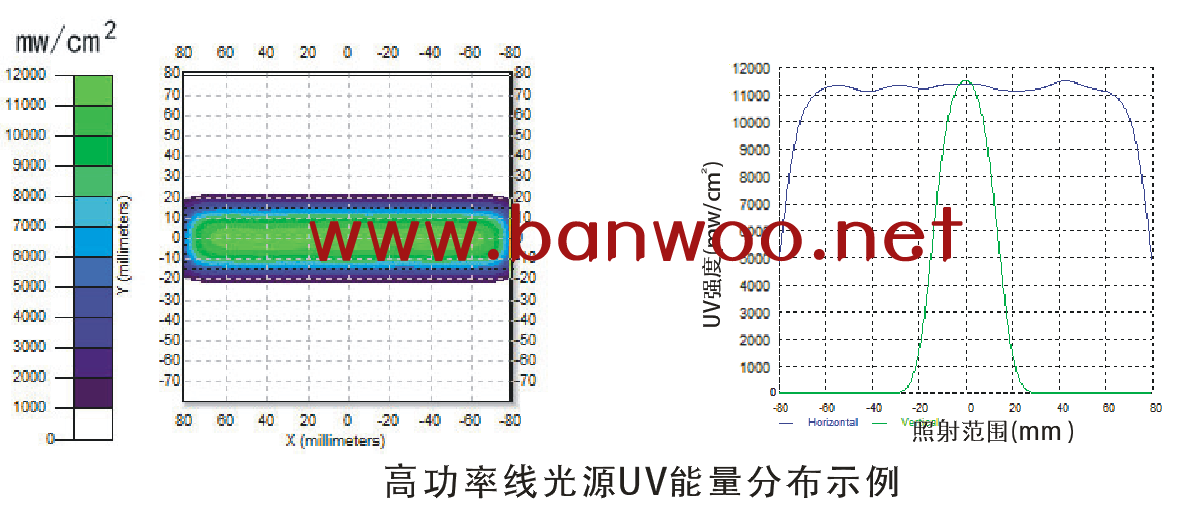

The light energy is expressed by MJ / cm2 and measured by a light energy meter. In the case of fixed UV intensity, UV energy = UV intensity * time.

Here we should emphasize that the UV intensity must be a stable value. If the UV intensity is not stable, when it is large, when it is small, this formula will not hold. It is also thought that UV energy / time = UV light intensity. In the same way, if the UV light intensity is a stable value, then the UV light intensity calculated by this formula can only be said to be the average value of the light intensity.

Relationship between energy and curing

We all know that the curing properties, namely photosensitivity, of different photoresists are different. The photosensitivity of photoresists can be characterized by two characteristic parameters, i.e. critical exposure e, transmission depth D, and critical exposure refers to the minimum energy required by the liquid layer of photoresists when they are cured by photopolymerization under UV irradiation. The photosensitivity of photoresist is also closely related to its transmission depth. The transmission depth d refers to the depth when the UV energy density in the photoresist decays to 1 / E of the incident energy density e, which is an indicator of the absorption of UV energy by the photoresist.

1. When we purchase the UVLED curing equipment, we all know that we need to purchase the curing equipment with moderate energy according to the curing characteristics of the required curing products. The energy can neither be excessive nor insufficient, because when the UVLED energy is insufficient, it will cause incomplete curing, but when the energy is too high, it will cause excessive curing of the products, which may cause cracking, physical distortion and color change And so on.

2. The energy varies with the distance of the object, the voltage and current of the external power supply, and the quality of the UV lamp. For example, the optimal distance is 15-20cm, which produces a lot of light energy, and which power of UV lamp should be selected according to the width of the UV machine and the needs of the product.

3. As mentioned earlier, energy = light intensity * time, but this formula does not hold when the energy is unstable. However, with the increase of using time and the influence of using environment temperature, the output UV light intensity will continue to weaken, so the energy will also be affected.

What about not enough energy?

Sometimes, although the lamp can be lit normally, the effect of the equipment is much worse than before. At this time, we need to consider comprehensively whether the curing adhesive itself, power, UV energy, etc. are affected? If the detection is caused by the relationship between UV energy. Try the following:

1. The energy needed can be obtained by reducing the speed: it is found that the poor drying of the product may be caused by the insufficient energy of the UV lamp, or by the quality change factor of the ink / varnish itself. However, both can achieve the desired drying effect by reducing the speed. As long as you remember what you need for each correct drying: MJ / cm2, you can adjust yourself.

2. If it is caused by the low temperature and high humidity in the workshop, for one thing, the indoor temperature and humidity should be adjusted, generally 15-25 ℃ is suitable, and attention should be paid to avoid direct sunlight during curing. Secondly, reduce the operation speed of the equipment and extend the curing time properly.

3. Sometimes, although it can be normally lit, the effect of the equipment is obviously poor. At this time, you can try to close down the distance of the illuminant. With the change of the distance, the intensity will be a little higher (except for special optical system), but if it still fails to meet the requirements, you need to replace a new lamp.

|